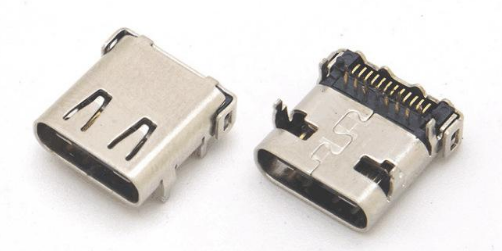

Study on ultrasonic-assisted brazing weldability of USB3.1 Type-C connector

发布时间:2023-02-16作者:Shenzhen BBJ technology co., LTD点击:927

There are many ways to connect bare copper conductor and copper terminal in USB Type-C connector, and brazing is the most reliable method. According to the directive issued by the European Union in 2003, the power electronic products entering the market from July 1, 2006 cannot contain six harmful substances: lead, mercury, cadmium, hexavalent chromium, PBB and PBDE. The development and popularization of lead-free solder is the inevitable result of market development. It is inevitable to use flux in conventional soldering, and it is difficult to clean the residual flux after soldering, which leads to the failure of connector insulation impedance and environmental pollution. Therefore, lead-free solder, new flux, related soldering equipment and soldering process in Type-C connector must be improved.

Bubujing Group uses SnXX lead-free alloy as brazing filler metal and applies ultrasonic-assisted brazing technology to connect the copper conductor and copper terminal in USB 3.1 Type-C connector. The ultrasonic vibration applied in the brazing process will produce cavitation effect in the molten solder, effectively remove the oxide film on the surface of the solder and the base metal, and improve the brazing process of the lead-free solder of the Type-C connector and the reliability of the welded joint.

Through relevant tests, Bubujing Group obtained the following results: 1. The connection of copper wire and copper terminal in Type-C connector was well realized by using SnXX solder ultrasonic-assisted brazing technology, and the solder joint morphology was smooth transition, the interface was well combined and there were no obvious defects. 2. The interface between 2.SnXX solder and copper wire and PCB is metallurgically bonded, and the compounds generated by the reaction are CugSng. It can prolong the ultrasonic action time and increase the thickness of compound layer, and the reasonable thickness of compound layer can increase the reliability of solder joint of Type-C connector.