Type-C plug salt spray test: an important part of ensuring product corrosion resistance

发布时间:2024-01-23作者:Shenzhen BBJ technology co., LTD点击:642

Type-C plug salt spray test: an important part of ensuring product corrosion resistance

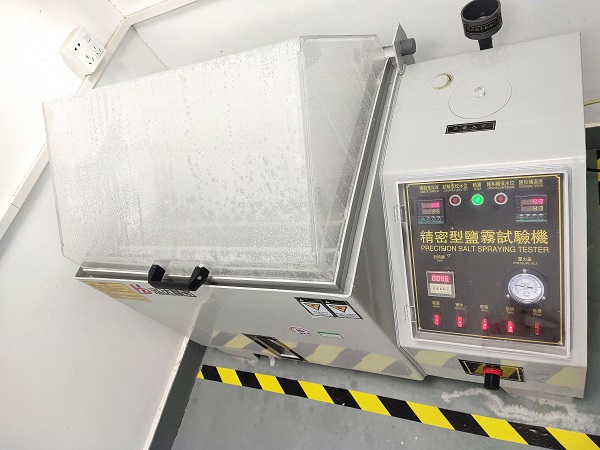

In the design and manufacturing of electronic products, the quality of Type-C plugs is crucial, and salt spray testing is an important part of ensuring its corrosion resistance. This article will delve into the key considerations and implementation steps of Type-C plugs in salt spray testing to ensure product reliability in harsh environments.

The Importance of Corrosion Resistance of Type-C Plug

As an important part of electronic products, Type-C plugs undertake the important tasks of data transmission and charging. However, in actual use, electronic equipment often faces harsh environments such as moisture, high temperature, and high humidity, so its plugs must have strong corrosion resistance. As a common environmental testing method, salt spray testing can simulate corrosion conditions in the marine environment and is crucial to ensuring the stability of Type-C plugs.

Key considerations for salt spray testing of Type-C plugs

1. Material selection and surface treatment: In the design of Type-C plug, it is crucial to choose materials with excellent corrosion resistance. At the same time, the use of effective surface treatment technologies, such as electroplating, galvanizing, etc., can improve the overall protective capabilities of the plug.

2. Sealing performance: Type-C plugs usually need to have certain waterproof performance to ensure that they are not damaged in humid environments. During the salt spray test, focus should be placed on testing the sealing performance of the plug to prevent salt spray from penetrating and causing corrosion.

3. Connector structural design: The structural design of the plug is directly related to the effect of the salt spray test. Properly designing the structure of the connector and reducing the gaps between components can effectively slow down the corrosion of the plug by salt spray.

Type-C plug salt spray test steps

1. Develop a test plan: Before conducting a salt spray test, you first need to formulate a detailed test plan to clarify the test time, temperature, salinity and other parameters. A reasonable test plan can more realistically simulate the actual use environment.

2. Sample preparation: Take representative Type-C plug samples from the production line for testing. Ensure sample quality and representativeness of production batches to obtain more instructive test results.

3. Equipment debugging: Carry out necessary debugging and calibration of salt spray testing equipment to ensure accuracy and reliability during the testing process. Equipment stability is critical to the comparability of test results.

4. Test execution: Place the prepared Type-C plug sample in the salt spray test equipment and conduct the test according to the established test plan. During the test, observe changes in the plug in time and record the test results.

5. Data analysis: After completing the test, conduct a detailed analysis of the test data. Pay attention to the corrosion on the surface of the plug and the stability of the connector to evaluate the corrosion resistance of the Type-C plug.

Through reasonable design and strict salt spray testing, the corrosion resistance of Type-C plugs can be effectively improved to ensure that they remain stable and reliable in harsh environments. We not only need to pay attention to the appearance and functionality of the plug, but also pay attention to its durability in actual use to improve the overall quality of the product. In an increasingly competitive market, continuous optimization of the design and testing process of Type-C plugs will help improve the market competitiveness of products.